Yemagetsi welding tsvimbo yekugadzira mutsara yakatevedzana ine advanced kugadzirwa tekinoroji, mhando yechigadzirwa yakagadzikana uye yakanyanya kugadzirwa, kumhanya kwakanyanya, uye kuita iyo coating ukobvu kufanana, yakatsetseka, yakaonda, mabhenefiti emhando yakagadzikana, zvakare inogona kuita kudzvanywa kweelectrode coating, kutamisa, kugaya musoro kukuya muswe, kudhinda, kuomesa uye kurongedza nzira kuti uone yakazara mechanization uye otomatiki kugadzirwa senge electrode kugadzirwa kwakanyanya.

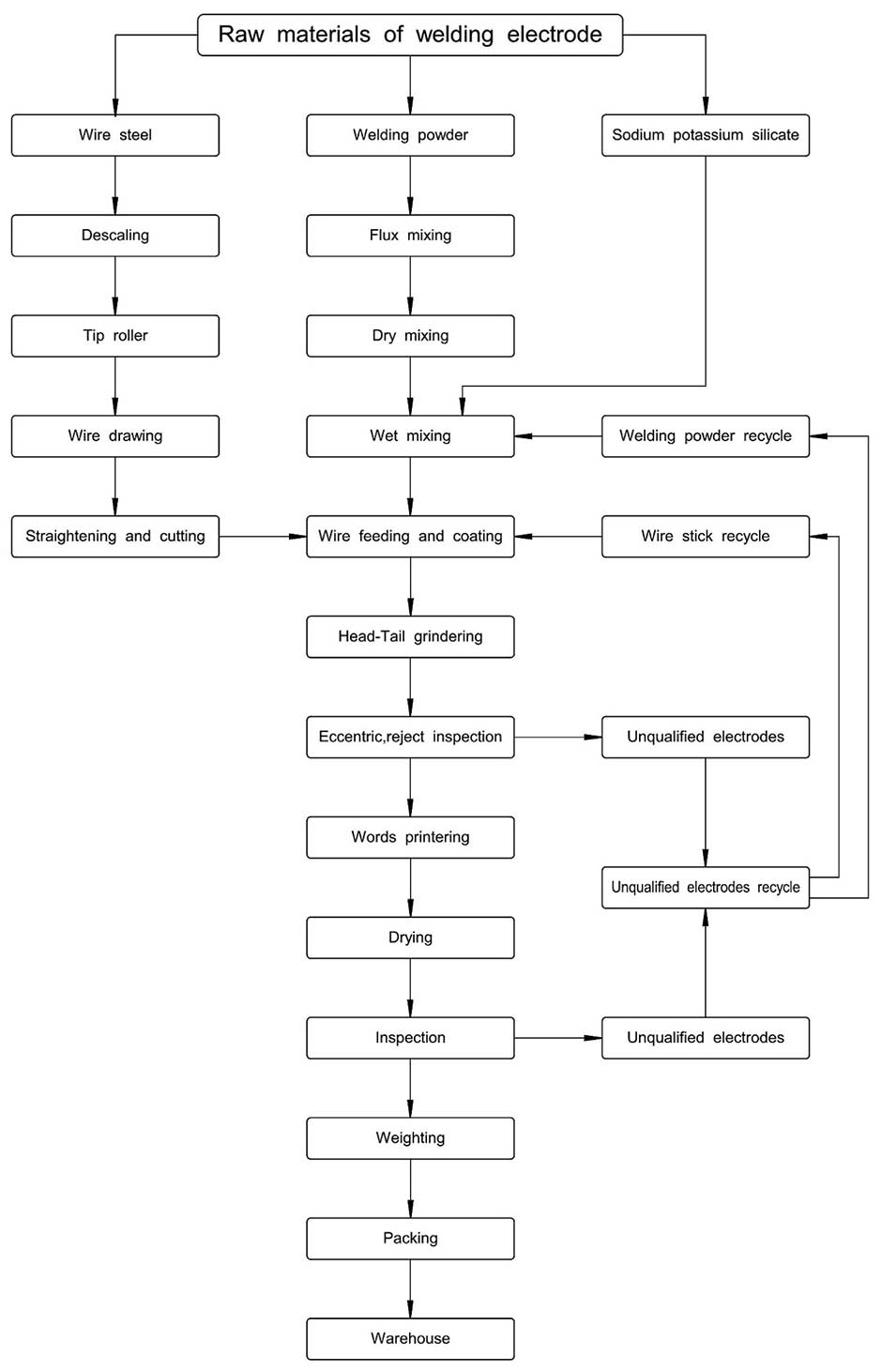

Welding electrode maitiro ekugadzira:

Waya yekudhirowa maitiro → Waya yekucheka maitiro → Flux yekusanganisa maitiro → Flux yekuisa maitiro → Kuomesa maitiro → Kudhinda maitiro → Kurongedza

Nhanganyaya yematanho ekushanda kwechigadzirwa

Nzira yekugadzira yewelding electrodekunyanya inosanganisira zvikamu zvitatu:

Core processing, Coating kugadzirirauyeElectrode Pressure Coating.

Iwo akasiyana-siyana emagetsi emagetsi ane hupfu (ore, ferroalloys uye zvigadzirwa zvemakemikari, zvichingodaro) zvinoenderana nechikamu chewelding rod formula yezvisanganiswa, inogona kuyerwa nemaoko kana yemagetsi komputa inodzora chiyero chemagetsi chekuyeresa otomatiki. Zvisungo zvinosanganiswa zvakaoma mumusanganisi kuti zvive yunifomu, uye zvishoma nezvishoma zvinodururwa muhuwandu hwakakodzera hwegirazi remvura (sebhainda), yakasimudzwa mune imwe viscosity yekuputira, inogona kutumirwa kumuchina wekudhinda wekuputira kuti utsikidze tsvimbo yemoto.

The welding rod press coating machine ndeye midziyo yakabatana. Basa rayo nderekusanganisa iyo yakanyorova pendi yekutsikirira coating kubva kune welding core, uye welding tsvimbo inosunga magumo uye lead arcs end processing, kuitira kuti chimiro chetsvimbo yewelding.

Features

| Zita | Welding electrode kugadzira mutsara |

| Function | Kugadzira otomatiki kwe electrode |

| Products | e6013, e7018 |

| Certification | CE, ISO9001 |

| Material | low carbon steel wire, galvanized wire kana ribbed waya. |

| Voltage | 380v/50HZ (seChikumbiro cheVatengi) |

Nyaya mharidzo

Iyo tekinoroji yekugadzira tekinoroji yakakura, iyo fomula inyanzvi, maitiro akanaka, iyo electrode arc kugadzikana, yakanyanya kunyungudika, kubviswa kwe slag. Iyo electrode ine arc yakagadzikana, yakakwirira deposition rate, yakanaka kubviswa slag, yakakwirira weld simba, uye yakanakisa welding performance.